A Comprehensive Guide to Recognizing Litho Printing Techniques

The world of litho printing, a strategy originating from the late 18th century, is a remarkable blend of background, art, innovation and science. This detailed guide will certainly untangle the complexities of this printing technique, from the structure of litho inks to the obstacles dealt with in modern applications. As we venture into the complexities of lithography, the value of automation and sustainability in guaranteeing its future importance becomes significantly clear. Stick with us as we journey right into the exciting realm of litho printing.

The Historical Development of Litho Printing

The historical trajectory of litho printing, a critical development in the world of communication, is a captivating tale of human ingenuity. The process progressed with the development of the rotary press, which considerably enhanced productivity. Each phase of litho printing's development showcases humanity's relentless quest of efficiency and quality in aesthetic interaction.

Decoding the Science Behind Litho Printing Inks

Progressing in the exploration of litho printing strategies, the focus currently moves to the science behind litho printing inks. The structure of these inks, their drying process, and shade mixing strategies create the backbone of this complex art form. Understanding these elements is crucial to grasping the craft and attaining the desired print outcomes.

Structure of Litho Inks

In lithographic printing, the fundamental function of litho inks can not be overemphasized. Pigments, the color-providing aspects, are finely ground fragments suspended in the automobile, a liquid that carries the pigment onto the printing surface area. Each part plays a crucial part in the last print's high quality, making the accurate formula of litho inks an elaborate science.

Ink Drying Refine

From the composition of litho inks, attention transforms to the fascinating procedure of ink drying out. The drying out procedure is essential, as it influences the last print's top quality and long life. 2 primary techniques are made use of in litho printing: oxidative drying and absorption. Oxidative drying entails the ink reacting with oxygen in the air to develop a hard, completely dry film. This method provides a durable finish, but can be slower contrasted to absorption. Absorption, on the various other hand, involves the ink leaking into the paper fibers, which is a quicker procedure however can cause less vibrant colors. The selection between these techniques is reliant upon aspects such as print rate needs, the paper kind utilized, and the preferred surface.

Color Mixing Strategies

While the drying process plays a crucial role in litho printing, the science of shade blending strategies holds equivalent value. This is a complex procedure that includes the cautious mixing of main shades: cyan, magenta, and yellow, in varying percentages to attain a wide range of hues. The addition of black ink, called 'key', assists in regulating the strength and deepness of the shades. The science behind litho printing inks likewise takes right into account the openness of the ink, which impacts exactly how colors overlay and mix. To achieve an effective color mix, print experts should additionally understand the details of ink habits, shade theory, and the physical buildings of the substratum on Our site which the ink is used.

The Art and Style Aspects in Litho Printing

Litho printing takes a breath life right into art and style through its unique aspects. Litho printing fits a variety of shades, enabling artists to create lively and dynamic prints. This combination of accuracy and convenience makes litho printing a recommended selection for lots of artists and designers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have located extensive usage in the contemporary business industry. Its impact and importance remain to expand with the arrival of new innovations and technologies in the field. This section will certainly check out these modern applications and the transformative function they play in the printing market.

Commercial Litho Printing Makes Use Of

In today's digital age, one may question the significance of conventional printing methods. Litho printing continues to be an important part of the industrial industry. High-volume printing tasks, such as the manufacturing of books, newspapers, and packaging, rely upon litho printing for its capability to provide superior picture quality and price performance. The process, which entails transferring a tattooed picture from a plate onto a rubber covering and after that to the printing surface area, offers unmatched uniformity. This makes it optimal for tasks calling for a large print run. Litho printing additionally supplies a broad shade spectrum, remarkable to that of electronic printing. This makes it the go-to option for tasks that demand vibrant, high-quality shade recreation.

Innovations in Litho Printing

Pressing the limits of conventional techniques, modern-day improvements have actually sustained a host of developments in litho printing. These developments have not only improved the top quality and efficiency of litho prints but likewise increased its application extent. One famous development is digital litho printing, which integrates the merits of electronic technology with litho's premium output. This crossbreed version supplies faster arrangement times, More hints reduced waste, and allows on-demand printing. One more significant development is the intro of eco-friendly inks. These inks, made from vegetable or soy-based remedies, have actually substantially minimized the market's ecological impact. litho printing. Additionally, the advancement of innovative plate innovation has structured the printing process, causing sharper pictures and improved color fidelity. These advancements highlight the enduring importance of litho printing in the modern-day world.

Exploring the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

In spite of the accuracy and practice that litho printing happily upholds, it is not without its set of contemporary obstacles. The most common concerns include the high first configuration expense, difficulty in printing variable information, and environmental concerns as a result of chemical usage. However, options are becoming modern technology evolves. Digital litho printing enables economical short runs and simple personalization, resolving the concern of variable information. Environmentally-friendly inks and safer plate-making processes minimize ecological worries. Additionally, developments in automation have actually reduced labor expenses, better democratizing the lithography process. Therefore, while there are difficulties, the litho printing industry is proactively adapting to satisfy them head-on, guaranteeing its importance in the future.

Verdict

In final thought, litho printing, with its rich background and clinical details, holds a substantial place in the print market. The future of litho printing hinges on its capability to adapt to these transforming demands, attesting its long-lasting worth in an evolving market.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Jane Carrey Then & Now!

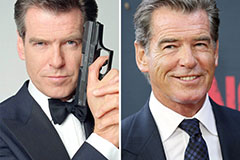

Jane Carrey Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!